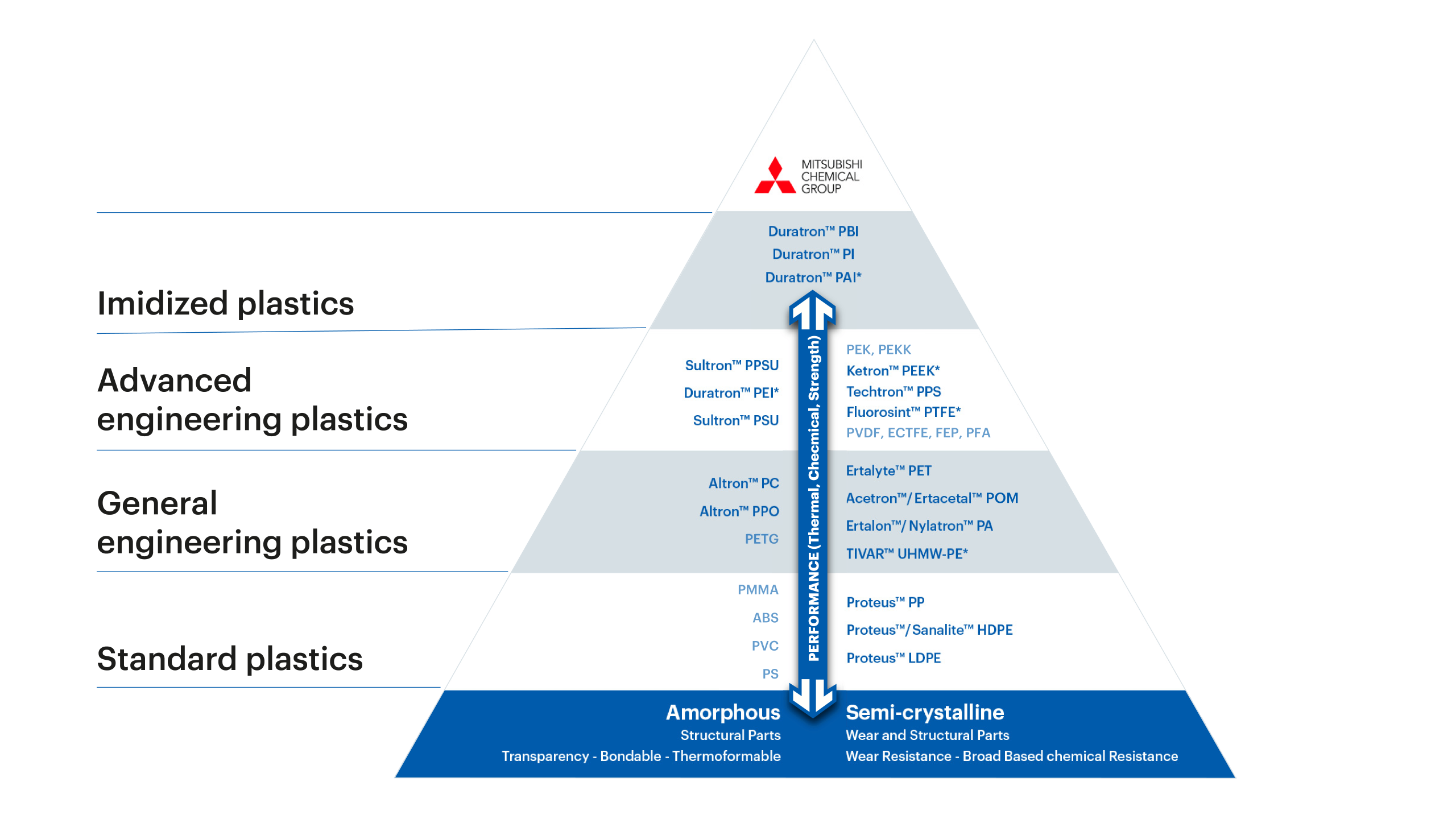

When your customer needs a plastic that can take on punishing heat or aggressive chemicals, Duratron™ polyimides (PI) and polybenzimidazole (PBI) stand ready. From outer space to advanced computer chip manufacturing, customers often select both of these specialty polymers to deliver the strength, stability, and reliability needed when failure isn’t an option.

Mitsubishi Chemical Group (MCG) stocks both specialty solutions to help you meet high-stakes specifications with confidence. Our team is ready to back you with decades of experience, technical data, and expert support to make selling these specialty materials easier.

Why Engineers Choose Duratron™ PI and PBI

- Built for extreme heat—Maintain mechanical properties longer where most plastics soften.

- Chemically resistant—Better at withstanding aggressive solvents, corrosive environments, plasma, and high-temperature oxidation.

- Trusted in many mission-critical uses—Common in aerospace, semiconductor manufacturing, and high-temperature electrical components.

- Low outgassing—More stable in vacuum and cleanroom applications.

Did You Know?

PBI was originally developed as a burn-resistant material for NASA space suits. While harder to process, it delivers rare performance—often holding strength beyond 700°F—where many engineers turn to ceramics or soft metals instead.

How They Compare

After exploring melt-processible imides like polyetherimide and polyamide-imide (PAI), it’s worth looking at their higher-heat relatives: PI and PBI.

While PEI and PAI are both excellent choices for impressive heat resistance and strength at a lower cost, PI takes several steps further. Rather than melting and re-forming like typical thermoplastics, pure polyimides behave more like thermosets, relying on heat and pressure to fuse fine powders or casting from solvents. This makes them more specialized to produce, but the payoff is big: Polyimides can handle much higher temperatures, resist chemicals even better, and stay stronger where other plastics break down.

Born from early aerospace and defense research in the mid-20th century, Duratron™ PI and PBI belong to the same family of aromatic, high-temperature polymers. Though closely related, each brings its own distinct advantage.

| Property |

Duratron™ PI |

Duratron™ PBI |

| Continuous Use Temperature (CUT) | 500°F (260°C) | >700°F (370°C) |

| Strength retention at heat | Excellent | Exceptional |

| Processing | Hot compression molding or solvent casting | Hot compression molding |

Think of Duratron™ PI as the go-to workhorse for continuous service above 500°F, and Duratron™ PBI as the higher-temperature sibling for the harshest conditions. Together, they bridge the gap between thermoplastics and ceramics, delivering unmatched performance in truly extreme environments.

TIP! If the job needs continuous service above 500°F, low outgassing, or resistance to aggressive chemicals, start your testing with Duratron™ PI or PBI. For slightly lower requirements, consider Duratron™ PEI or PAI first.

Typical Parts and Industries

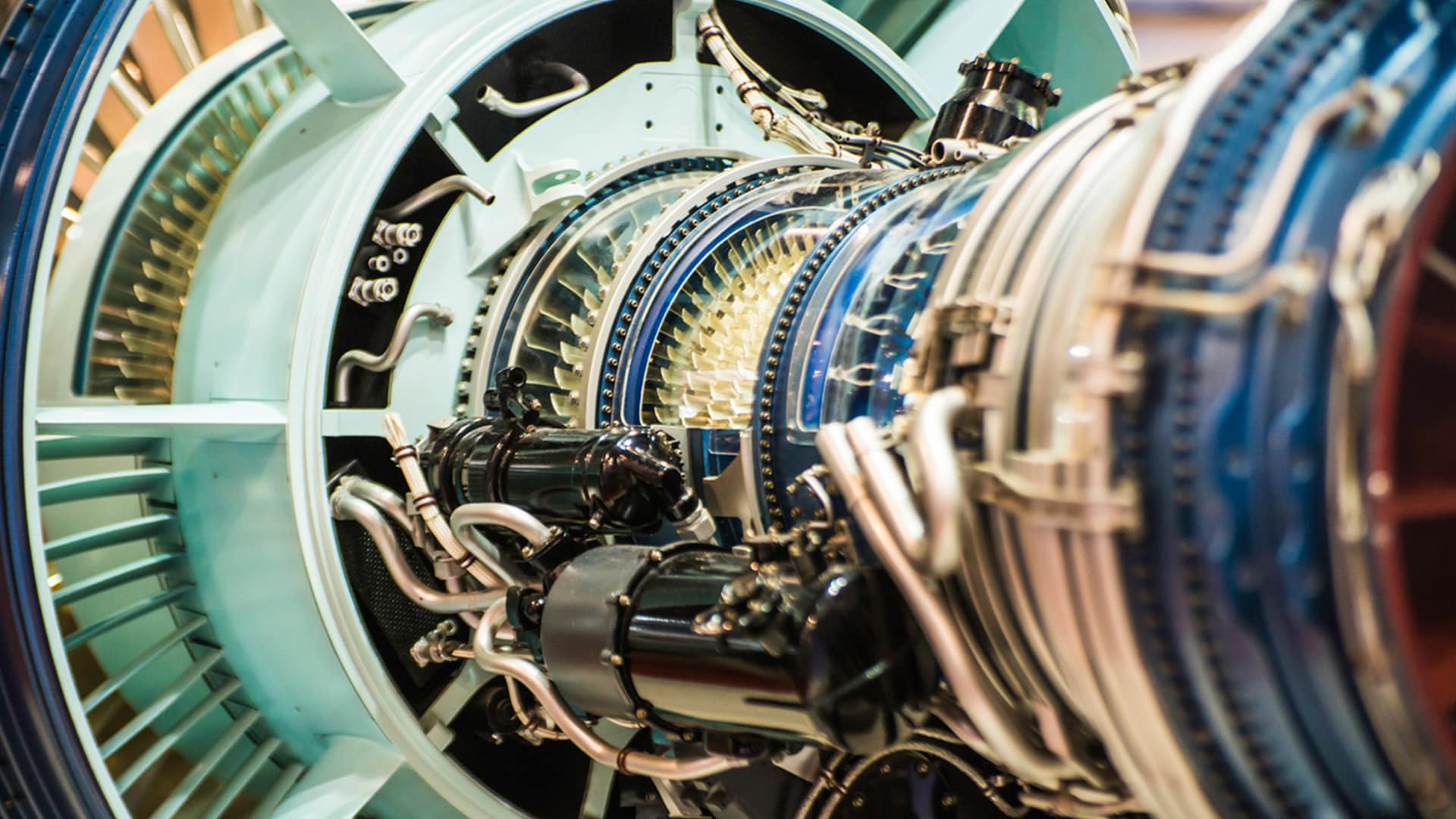

AerospaceValve seats, insulators, and structural components, especially those operating near a heat source like inside the engine nacelle. |

SemiconductorTooling, wafer handling, and chamber components exposed to plasma. |

Electrical/electronicsHigh-temp connectors and insulating parts at high frequency. |

IndustrialSeals and bearings in high-temperature service. |

|

Talking Points for Customer ConversationsWhen recommending PI or PBI, help customers weigh:

MCG can help you navigate all three by balancing cost, manufacturability, and long-term performance for your customer. |

MCG is here to help you win.

We supply proven specialty solutions tailored to demanding specs.

Need help deciphering design tradeoffs, processing options, and grade selection?

Contact us to get started.

Simplify Your Workflow with MCAM Connect

Easily manage orders, access critical data, and get tailored support — all from one powerful platform.