When your customers demand high performance, Ketron™ PEEK delivers. However, even the best resin can fall short if the shape isn’t processed with care. That’s why Mitsubishi Chemical Group (MCG) focuses on doing it right, every time.

Processing You Can Trust

At MCG, processing Ketron™ PEEK starts with only qualified, high-viscosity resins. From there, our locked-down process does the heavy lifting:

- Statistical process controls ensure the resin properties are well maintained in the extruded or molded shape

- Advanced digital monitoring from resin drying through annealing checks that shapes meet agreed-upon specifications

- Precise extrusion tooling and run conditions have been fine-tuned over the past 40 years of processing PEEK resins in Europe and North America

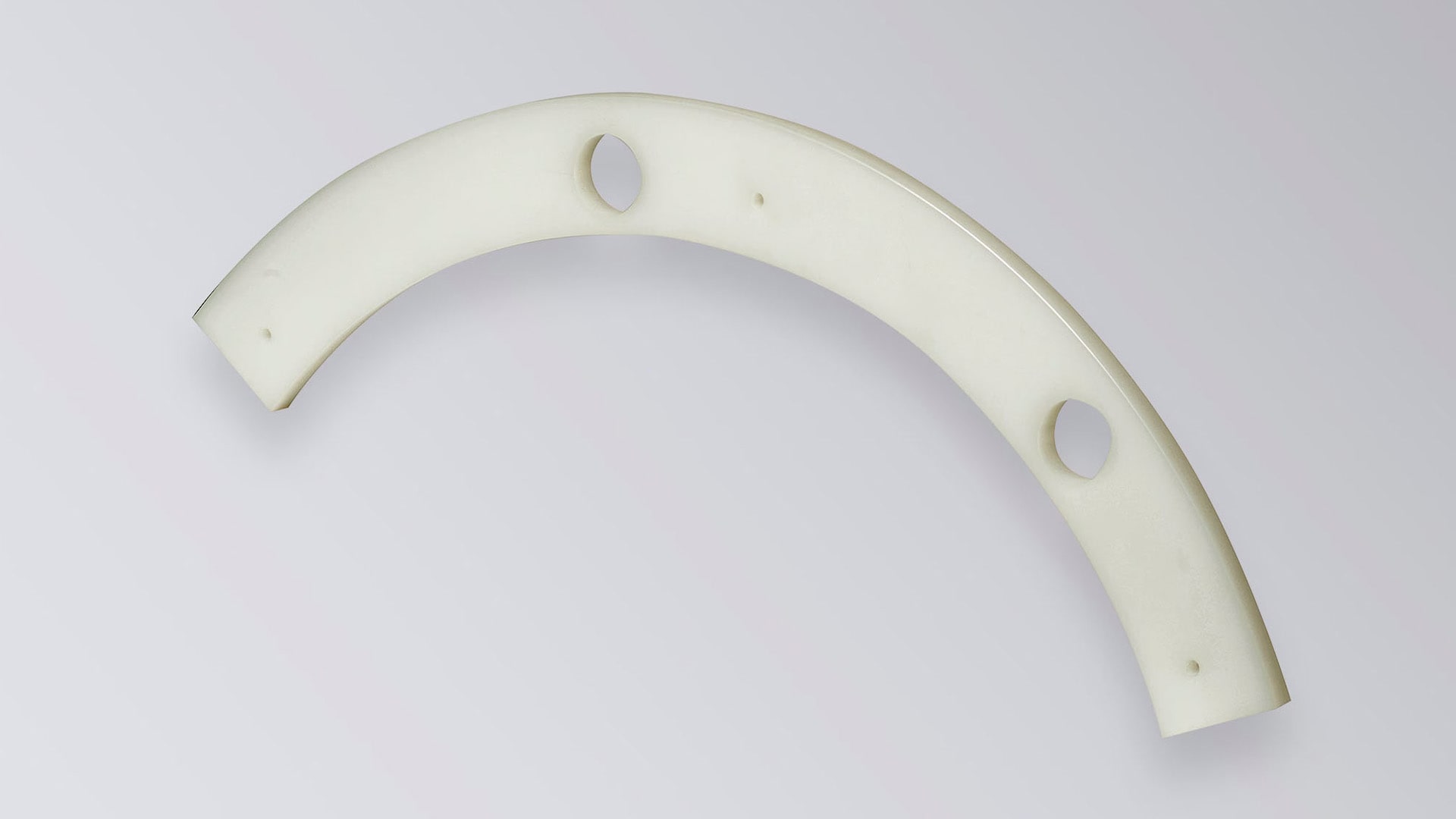

Near-Net Shapes Built for Efficiency

When yield matters, near-net injection molded shapes and tubes are the smart choice. Our Ketron™ PEEK near-net solutions can help you:

- Cut machining time

- Reduce waste

- Maximize part yield

Our shapes and parts machine clean, remain reliable, and save you and your customers time and material.

The Widest PEEK Portfolio in the Industry

No one offers more choices than MCG. With more than 20 Ketron™ PEEK grades, we can help you match the right material to every application.

Description |

Extruded Shapes |

Compression Molded |

Injection Molded |

Spun Cast |

| Non-reinforced general-purpose PEEK | Ketron™ 1000 | Ketron™ IM 1000 | Ketron™ SP 1000 | |

| Non-reinforced PEEK based on Victex 450G resin |

Ketron™ FK |

|||

| 30% glass-fiber reinforced PEEK | Ketron™ GF30 | Ketron™ CM GF30 | Ketron™ IM GF30 | Ketron™ SP GF30 |

| 30% carbon-fiber reinforced PEEK | Ketron™ CA30 | Ketron™ CM CA30 | Ketron™ SP CA30 | |

| Low-friction wear grade with PTFE and graphite PEEK | Ketron™ HPV | Ketron™ CM HPV | ||

| PTFE-filled, EU food grade PEEK, blue | Ketron™ TX | |||

| Medical grade PEEK, pre-assessed for ISO 10993 and USP requirements | Ketron™ LSG | |||

| Cryogenic capable PEEK for structural applications | Ketron™ CRS | Ketron™ IM CRS | ||

| Cryogenic capable PEEK for dynamic wear applications | Ketron™ CRD | Ketron™ IM CRD | ||

| Metal and x-ray detectable PEEK, blue | Ketron™ VMX |

What Customers Say About Ketron™ PEEK

| “ |

Ketron™ PEEK is the cleanest of all the PEEK shape producers. We never find black specs [or] inclusions. |

| “ |

We screw machine small PEEK parts and love the precision ground Ketron™ rod. It’s straight with a very consistent outer diameter rod-to-rod and lot-to-lot. |

| “ |

We struggled holding the inner diameter of a tight tolerance part until we started using Ketron™ 1000 rod. Now we can easily hold +/-.0005″. |

| “ |

I appreciate that we can find both Victrex PEEK and Ketaspire PEEK in shape form made to the same high-quality standards in such a wide range of sizes and shapes. |

| “ |

Extruded 2.75″ x 2″ Ketron™ 1000 tube has improved my yield and throughput over both rod and 6″ length injection molded tube. And the material is super stable. |

Let’s talk PEEK!You don’t have to sort through the options alone. Whether you’re solving for yield, specs, or part life, we’re here to help. Contact us. |

Simplify Your Workflow with MCAM Connect

Easily manage orders, access critical data, and get tailored support — all from one powerful platform.