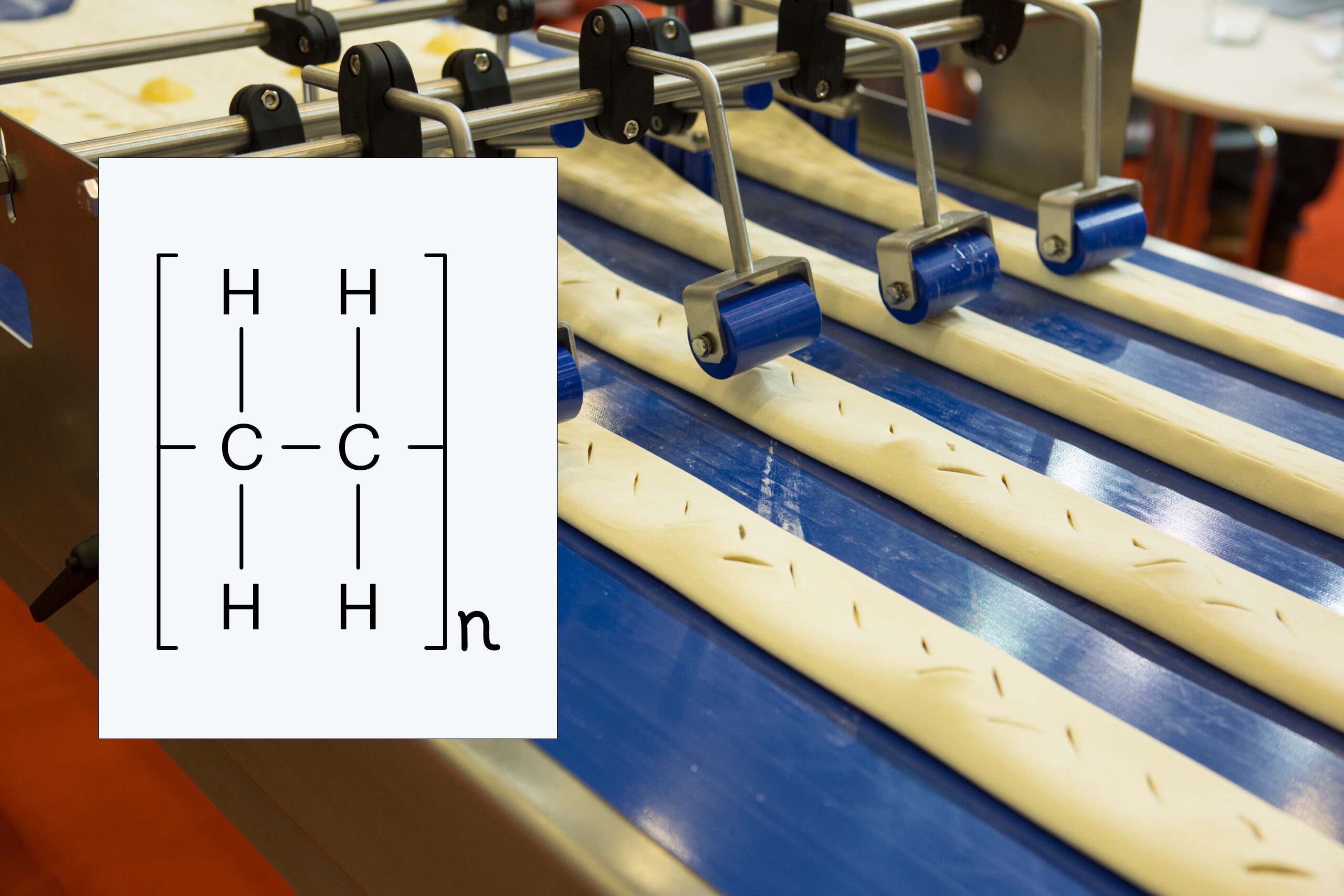

Plastics are engineered polymers—long chains of repeating chemical units called monomers. While natural polymers like proteins, DNA, and wood exist, engineered polymers allow us to precisely control basic properties like strength, durability, and processability. One of the best examples? Polyethylene.

The Power of Molecular Weight

The ethylene monomer consists of just two carbon (C) and four hydrogen (H) atoms. The “n” in the molecule to the left represents the number of repeating units. By linking these molecules together, we create materials with vastly different properties:

- Low molecular weight (n=100)—Soft, wax-like material (think candle wax)

- Medium molecular weight—Includes low-density polyethylene (LDPE) used in grocery bags and high-density polyethylene (HDPE) for fixtures and welded tanks

- Ultra-high molecular weight (UHMW) (n=1M+)—Tough, inert, and wear/abrasion-resistant TIVAR® UHMW polyethylene for demanding applications

TIP! Two Key Rules to Remember

- Higher molecular weight = stronger, tougher, more durable material. Think about the difference between a candle and a UHMW material—they share the same chemistry, but molecular weight transforms their performance.

- Higher molecular weight = higher viscosity when molten. At a certain point, the material becomes too thick to be melt extruded. That’s why UHMW materials are compression-molded or ram extruded instead.

Which Process Delivers Higher Performance?

- Injection molding uses lower molecular weight resins that flow more easily, helping make parts more quickly at the expense of toughness and wear/abrasion resistance

- Machined parts from extruded shapes come from higher molecular weight resins, offering superior durability and wear resistance

The bottom line? When you’re after strength and durability, machined UHMW parts outperform injection-molded parts every time.

Have a question?We’re here to help. Contact us to chat about your next challenge. |

Simplify Your Workflow with MCAM Connect

Easily manage orders, access critical data, and get tailored support—all from one powerful platform.