Ertalyte™ polyethylene terephthalate polyester (PET-P) has been trusted by machinists and designers for over 40 years. Why? Three key reasons keep it at the top of the list.

1. Precision Starts with Processing

Machining-quality PET-P takes more than just melting resin and forming shapes. At Mitsubishi Chemical Group (MCG), we’ve refined our Ertalyte™ PET-P process since the early 1980s—starting with the cleanest, highest-viscosity polyethylene terephthalate (PET) resin base available. Only two resins make the cut, both pre-crystallized and globally approved for consistency. At MCG, we:

- Carefully dry resins to maintain molecular weight

- Monitor multiple extrusion parameters in real time

- Use proprietary annealing cycles to minimize internal stress

The result? Ertalyte™ PET-P machines like other plastics, but with dimensional stability more like aluminum.

2. Performance Beyond Basic PET

Ertalyte™ PET-P performs well on its own. For more demanding applications, we offer enhanced grades. These grades help extend part life, improve reliability, and reduce replacement cycles.

Ertalyte™ TX PET-P |

Ertalyte™ SLP PET-P |

|

|

3. Backed by Experience You Can Count On

When you choose Ertalyte™, you get more than just material. You get access to:

- Machining advice and best practices

- Design guidance for your application

- Expert support from a team with 50 years of PET-P knowledge

MCG is here to help you spec the right grade, shape, and design—every step of the way.

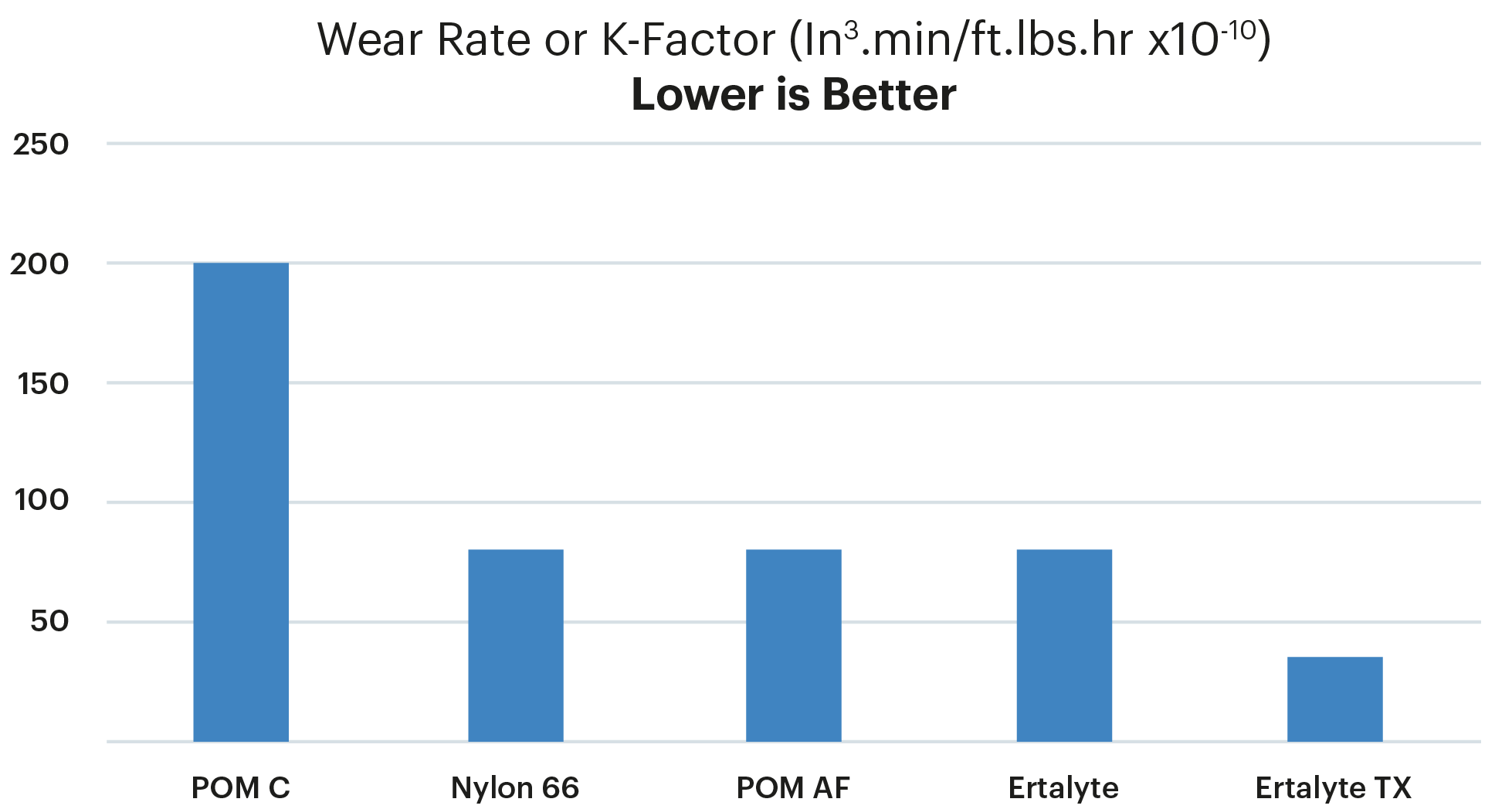

Grade Highlight: Ertalyte™ TX PET-P Delivers Top Wear Resistance

This chart compares the wear resistance of six common materials. A lower wear factor means better wear performance—an area where Ertalyte™ TX PET-P is superior. Its ability to maintain enhanced surface integrity under pressure makes it ideal for demanding, high-load applications.

Tips for the Best Machining Results with Ertalyte™ PET-P

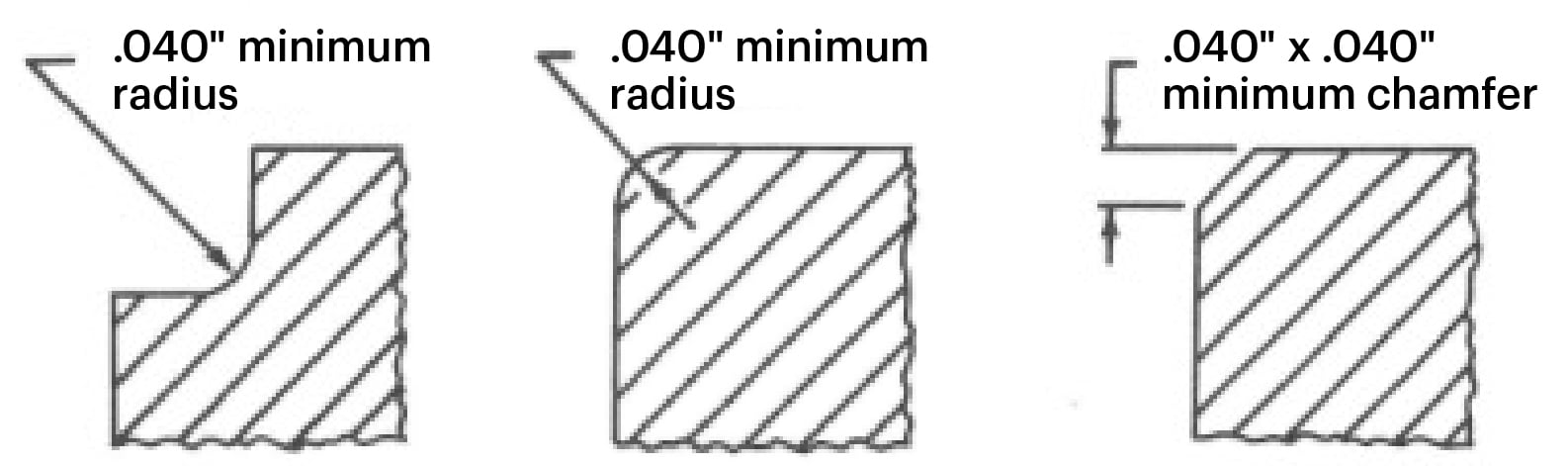

Ease the edges. Radius, chamfer, or round all corners to at least 0.040″.

Mind your spacing. Keep at least one hole diameter between holes or between a hole and an edge.

Prefer press-fits. For internally pressurized parts, press-fits into straight-sided holes are better than over-drilled and tapped threads.

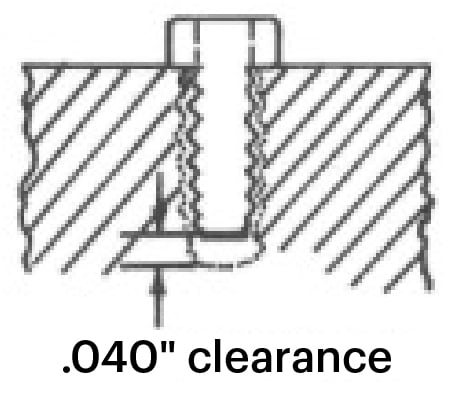

Thread with care. If using threaded fasteners, leave clearance at the bottom of a drilled or tapped hole.

Let’s talk!If you’re looking to solve a material challenge—or just need a second opinion—we’re here. Let’s talk about how Ertalyte™ PET-P fits your next job. Contact us. |

Simplify Your Workflow with MCAM Connect

Easily manage orders, access critical data, and get tailored support — all from one powerful platform.