Sustainability and cost don’t have to compete.

With Mitsubishi Chemical Group (MCG) Smartcast* technology, you can achieve both in cases where nylon fits the design and production volumes justify a tooling investment.

Sustainability Built In

Smartcast* solutions help bridge the gap between machining and injection molding by doing more with less. Traditional machining starts with complex parts that require significant material removal. That scrap not only adds to waste, but also inflates machining time, energy, and cost.

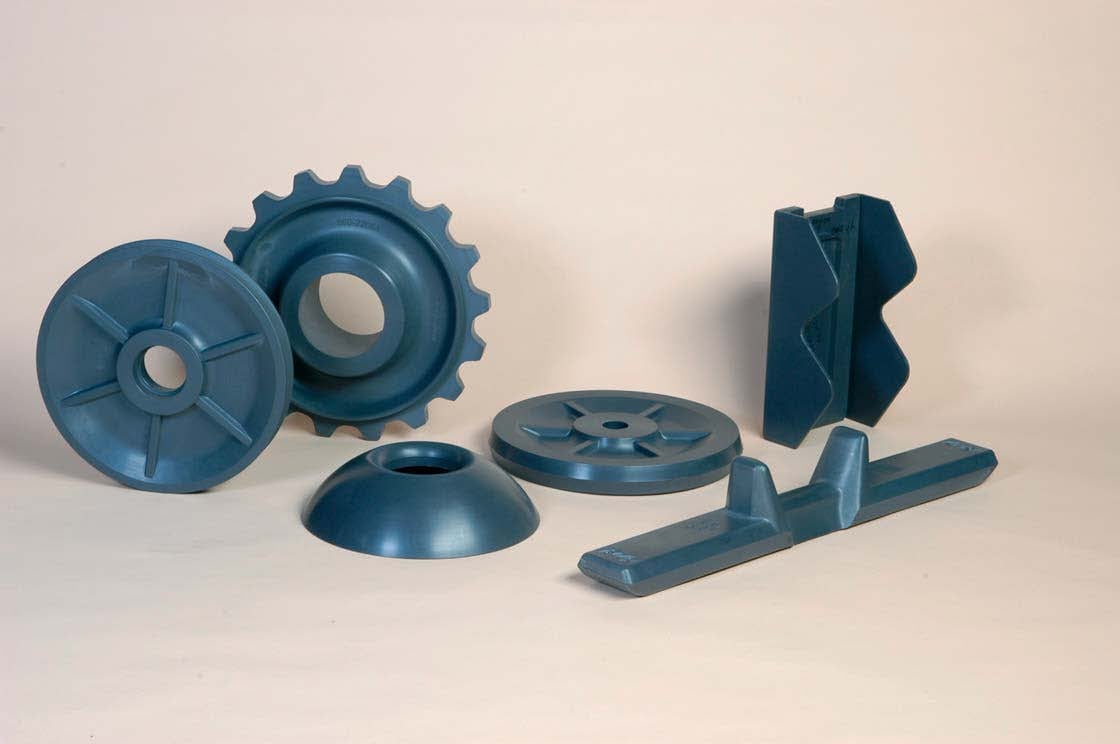

Smartcast* solutions help resolve that by using a closed mold, allowing machinists to cast near-net shapes with complex details—eliminating much of the waste before machining even begins. The more parts produced, the more savings grow. Smartcast* solutions also deliver the strength and wear resistance of Nylatron™ cast nylon 6 for a longer part life.

Compared to machining from standard shapes, Smartcast* solutions offer:

Reduced waste—Less material removal means lower scrap rates and saved costs

Improved efficiency—Near-net shapes reduce machining time

Scalability—Large, complex parts without expensive tooling

Durability—Parts last longer for demanding applications

Reducing Waste in the Field

The challenge: When MCG engineers redesigned 18″ x 18″ outrigger pads, the goal was to use less and last longer.

The solution: Replacing ultra-high molecular weight (UHMW) polyethylene with Nylatron™ cast nylon 6 improved both performance and material efficiency. Smartcast* solutions allowed the new pads to be formed with intricate ribs and webbing. Custom, cast-in features including a logo, handle, and mounting slots along with a matte finish that improved the look and feel of the parts, reinforced a positive image for the original equipment manufacturer (OEM).

Results:

Want to see how Smartcast* solutions can support your sustainability goals?Let’s talk. Our team is here to help. |

*Trademark pending

Simplify Your Workflow with MCAM Connect

Easily manage orders, access critical data, and get tailored support — all from one powerful platform.