Polyamide-imide (PAI) is one of the toughest resins to process, yet one of the highest performing. That combination makes it rare—and valuable to engineers and designers working with high-demand applications. Only two companies worldwide can melt-process PAI into rod, plate, and tubular shapes. Mitsubishi Chemical Group (MCG) is the larger of them. We learned how to extrude and cure this material in the 1980s and have been mastering it ever since.

Why Don’t More Companies Process PAI?

High resin cost, long cure times, and material variability all make PAI a challenging addition to any delivery program. Other reasons include:

- PAI doesn’t fully melt like other thermoplastics

- When heated up for extrusion, it flows like wet cement

- As it moves through equipment, PAI gets even thicker due to chemical reactions that help strengthen it

- PAI is highly sensitive to shear and any moisture in the mix can reduce its performance

- Each shape requires a multi-week cure cycle to build up thermal and mechanical properties like wear resistance, chemical stability, and impact resistance

MCG Difference

Processing PAI demands time, capital, and care. At MCG, we offer more sizes and shapes, manage the complex cure cycle, and deliver high-performance shapes when you need them. When you specify Duratron™ PAI, you can trust what shows up. Our team monitors every batch closely, running destructive tests throughout the process. We inspect every shape during and after production runs for camber, machinability, cleanliness, and dimensional accuracy.

How to Choose the Right Duratron™ PAI Grade

Step 1: Decide the size and shape needed.

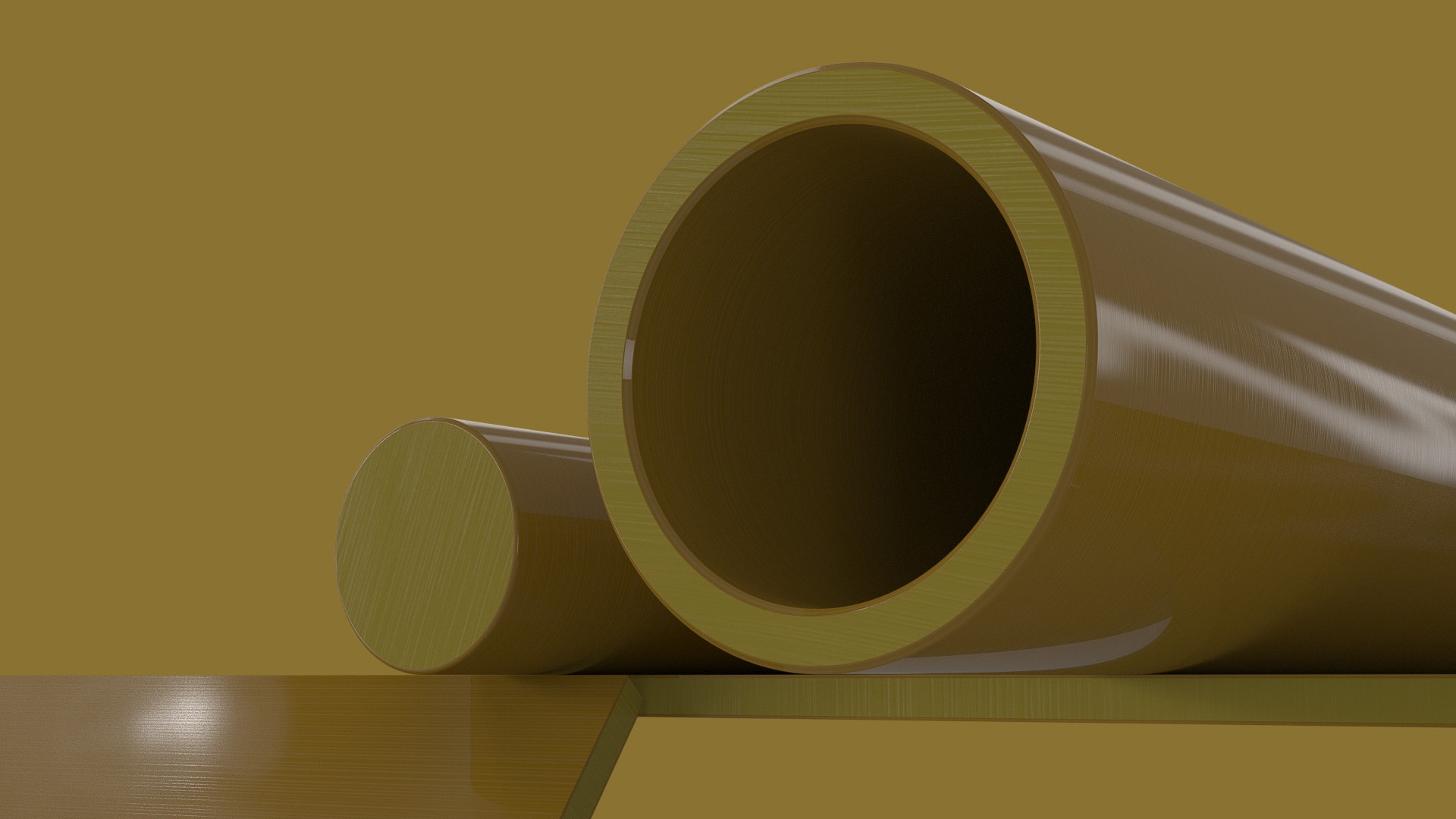

We offer two shaping options, each with unique processing paths:

Extruded shapes |

|

Highest performance.

|

Compression molded |

|

Small quantities of tubular shapes and unique recipes (especially when extruded sizes are not available). Great for smaller volumes or custom sizes.

|

Step 2: Find your fit.

We offer multiple grades to support different application needs:

Grade Type |

Key Properties |

Extruded Shapes |

Compression Molded |

| Non-reinforced | Superior impact strength, insulation | Duratron™ T4203 | Duratron™ T4503 |

| Wear | Low friction, excellent wear resistance | Duratron™ T4301 | Duratron™ T4501 Duratron™ T4540 |

| Glass-reinforced | Added stiffness, strength, and insulation | Duratron™ T5030 | Duratron™ T5530 |

| Carbon fiber-reinforced | High stiffness, strength, and dimensional stability | Duratron™ T7130 | Duratron™ T7530 |

| Aerospace | Dimensional stability over wide temperature range | Duratron™ T4301 AE Duratron™ T4203 AE |

We’re here to help.Not sure which grade of Duratron™ PAI fits your customer’s specifications? Contact our team via telephone, email or LiveChat.

|

Simplify Your Workflow with MCAM Connect

Easily manage orders, access critical data, and get tailored support — all from one powerful platform.