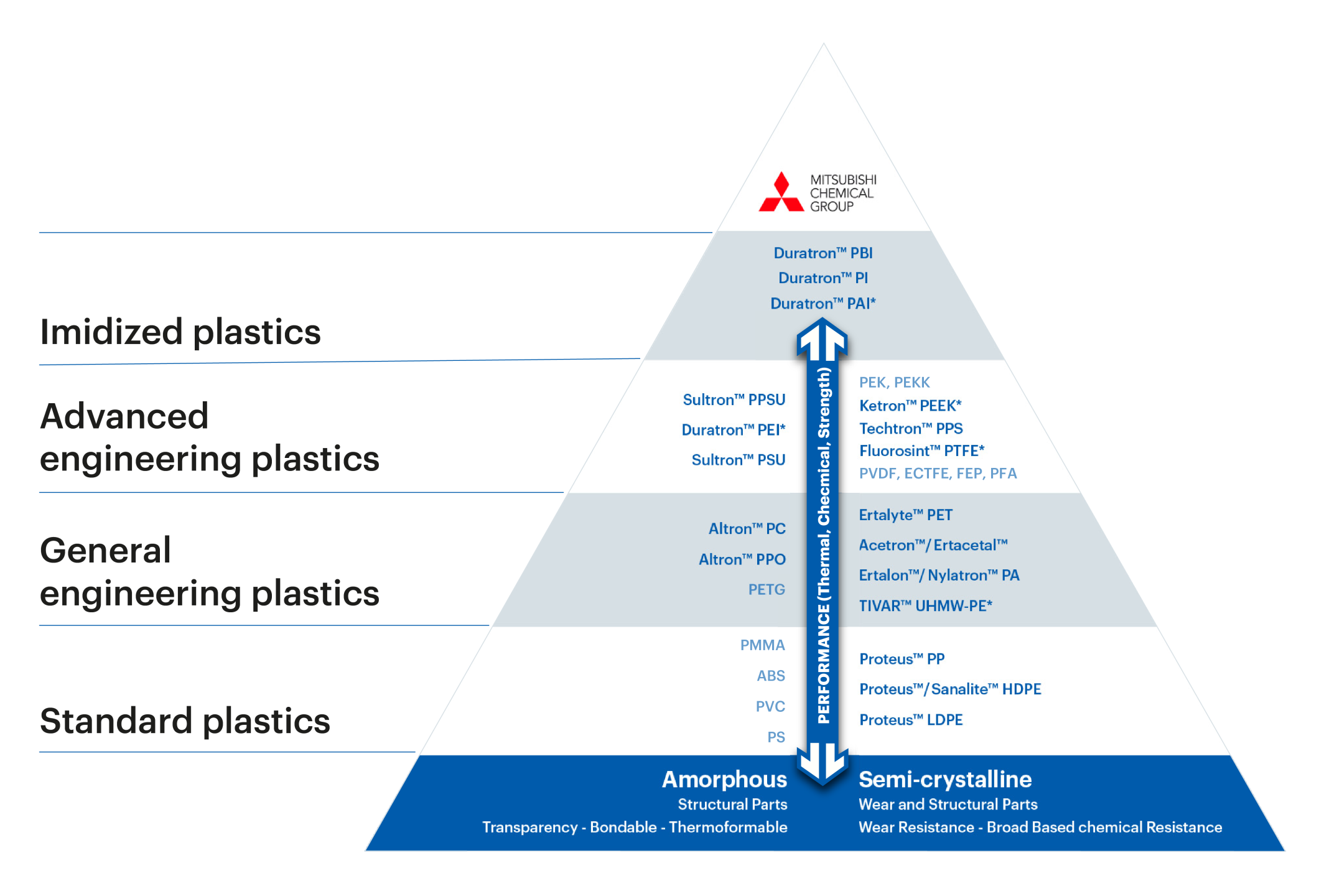

Polysulfone (PSU), polyphenylsulfone (PPSU), and polyetherimide (PEI) form the core of the amorphous advanced engineering plastics section of the materials triangle. These plastics often compete with each other—especially within the medical market—and can seem nearly identical when comparing physical properties.

Need help finding the right amorphous polymer for the job? Mitsubishi Chemical Group (MCG) offers Sultron™ PSU/PPSU and Duratron™ PEI stock shapes—and is here to help clarify the differences and guide you to the right choice.

A Brief History

In the 1960s–80s, GE Plastics and Union Carbide drove an “arms race” of amorphous polymers. Each new material outperformed polycarbonate (PC), carried a higher price, and carved out its own market niche.

PSU |

|

PEI |

|

PPSU |

|

*Trademarks are the property of their respective owners.

What MCG Supplies

After more than 30 years, MCG has helped make things simpler by focusing on PEI and PPSU for most machinable and stock-shape needs. Customers can choose from more than 10 grades. PSU remains available on a custom basis, and we can tailor specialty grades for unique applications.

Did You Know?

By naming Sultron™ PPSU or Duratron™ PEI on your internal specifications and drawings, you help ensure consistency, cleanliness, and compliance—even when third parties do the machining. Because Sultron™ and Duratron™ stock shapes are made from the name brand Udel®, Ultem®, and Radel® resins, you and your customers can trust that the parts you receive deliver proven performance and quality.

Choosing Between Sultron™ PPSU and Duratron™ PEI

These materials overlap in temperature range but are different in how they handle strength, sterilization, and electrical demands.

Similarities

- Temperature: Both withstand ~400°F (200°C), plus hot water and steam

- Availability: Both PEI and PPSU come in medical/non-medical grades, translucent/opaque options, and multiple colors

Where PEI shines

- Strength and Stiffness: PEI holds the edge well

- Electrical Performance: PEI excels, with dielectric strength >800 V/mil and stable behavior across temperature and frequency

Where PPSU shines

- Impact Resistance: PPSU is tougher and less notch-sensitive

- Sterilization: PPSU is best at tolerating repeated autoclaving

- Chemical Resistance: PPSU handles aggressive sterilants and cleaners better

When to Recommend Each

- Sultron™ PPSU: Choose when repeated sterilization, toughness, or chemical resistance matters most. Customers have selected it for: Orthopedic handles, reusable surgical trays, harsh cleaner environments

- Duratron™ PEI: Choose when electrical performance or maximum stiffness at high temperatures is critical. Customers have selected it for: Aerospace electrical connectors, high-frequency insulators

- Sultron™ PSU: Choose for proven hot-water resistance at a lower cost when peak performance isn’t needed. Customers have selected it for: Fluid fittings or housings where budget matters

If balance is needed, some of the tradeoffs are small, as you can see in the table below.

|

Sultron™ PPSU |

Duratron™ PEI |

Sultron™ PSU |

|

| Tensile strength (psi) | 11,000 | 17,000 | 10,200 |

| Heat deflection temperature at 264 psi (°F) | 405 | 400 | 340 |

| Continuous use temperature (°F) | 350 | 340 | 300 |

| Resistance to hot water/steam | Best | Better | Good |

| Izod impact—notched (ft-lbs/in) | 2.5 | 0.5 | 1.3 |

| Dielectric strength (volts/mil) | 360 | 380 | 425 |

Need help picking a grade?

If you’d like support comparing grades or need more data, contact us.

We’ll guide you to the best fit and help spec the right stock shape.

Simplify Your Workflow with MCAM Connect

Easily manage orders, access critical data, and get tailored support — all from one powerful platform.