In food processing and packaging, bearing choice matters. Especially when equipment must run quietly, cleanly, and without added lubrication.

The decision gets overwhelming fast with so many choices—like polyetheretherketone (PEEK), polyoxymethylene (POM), nylon, polyethylene, and more. Injection-molded bearings in every shape and size add even more to consider, offering advantages over sintered bronze bearings but competing for your attention. With more than 25 companies promoting “bearing grade” polytetrafluoroethylene (PTFE) blends with high wear and heat resistance, the options keep piling up. So, how do you make the right choice?

The MCG DifferenceMitsubishi Chemical Group (MCG) backs Fluorosint™ enhanced PTFE materials with real data and real results to help guide you toward the best-fit solution for your customers.

|

We Do the Testing—So You Don’t Have To

Our expert engineers have done their homework and completed side-by-side testing. The verdict is clear: Fluorosint™ enhanced PTFE materials outperform similar chemistries in high-demand bearing applications—especially when temperature, speed, and load all vary.

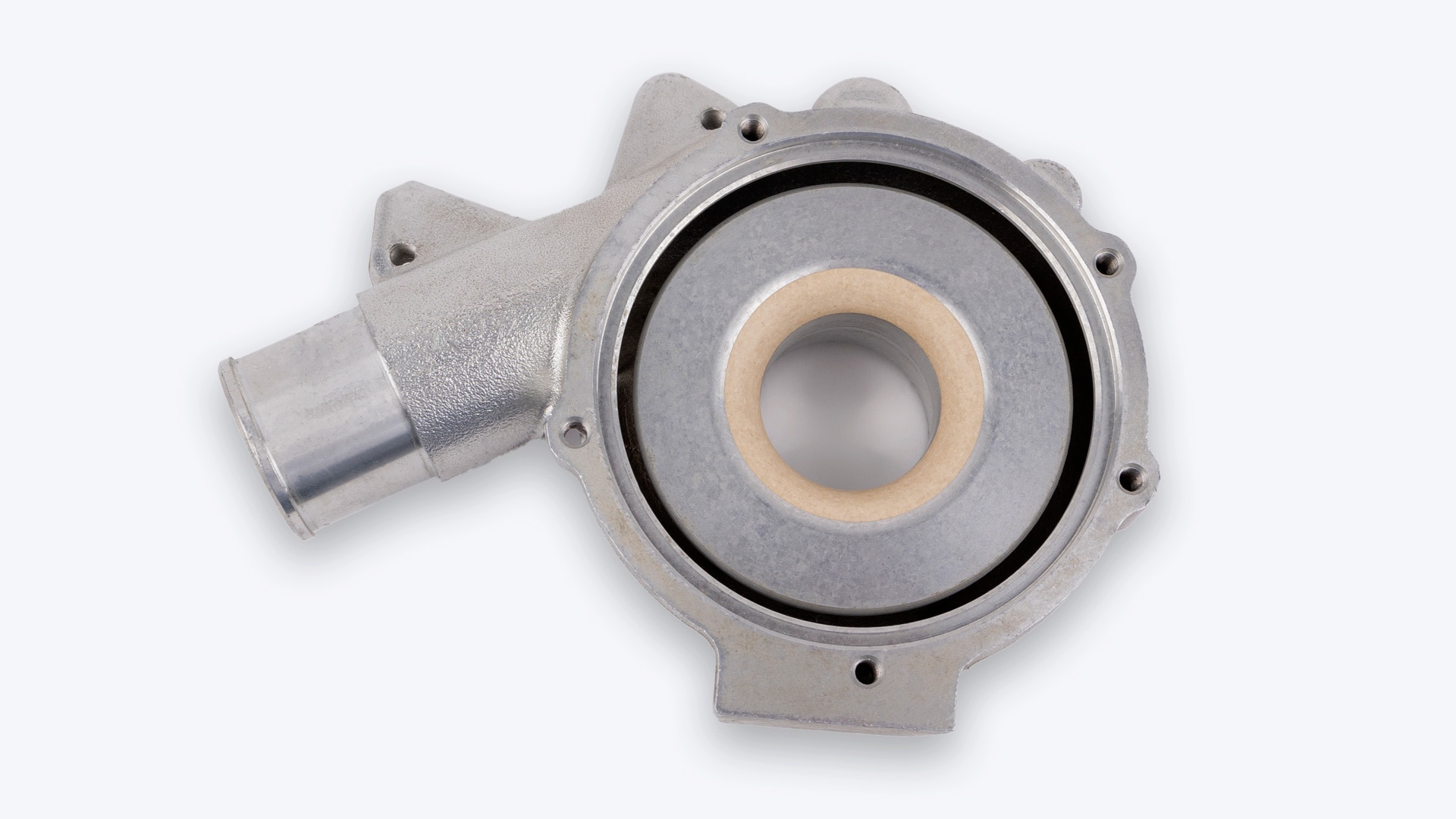

Fluorosint™ 207 and HPV are top picks for food and packaging environments that demand clean operation and low maintenance.

Where Fluorosint™ Bearings Perform Best

High-Speed Motion. Combines low friction with added strength and dimensional stability for journal bearings in motors, turbines, or spindles. |

Oscillating and Linear Movement. Delivers smooth, consistent motion for parts that slide, pivot, or reciprocate. |

No Added Lubrications. Reduces contamination and simplifies cleaning for food-grade use. |

Heat and Washdown Exposure. Resists deformation and wear in ovens and during chemical or sanitary wash cycles. |

Compare Key Properties

See how Fluorosint™ enhanced PTFE materials stack up against standard PTFE and other blends across key bearing performance properties—so you can confidently specify the right solution for your application.

Description |

Fluorosint™ 500 |

Fluorosint™ 207 |

Fluorosint™ HPV |

PTFE + Polyimide (gold) |

25% glass fiber PTFE |

PTFE |

| Compressive Strength (psi) | 4,000 | 3,800 | 3,000 | 3,000 | 2,500 | 1,500 |

| Shore hardness (Durometer) |

D70 |

D65 | D65 | D60 | D60 | D55 |

| Coefficient of Linear Thermal Expansion (in/in/°F x10-6) | 25 | 57 | 49 | 68 | 64 | 1008 |

| Coefficient of Friction | 0.15 | 0.10 | 0.15 | 0.20 | 0.20 | 0.05 |

| Limiting PV (psi-ft/min) | 8,000 | 8,000 | 20,000 | 15,000 | 3,000 | 2,000 |

| Wear factor (K) | 600 | 85 | 38 | 47 | 100 | 5000 |

| Deformation under load | 1 | 5 | 3.2 | 3.4 | 10 | 10 |

| Green: Shows strong advantage |

Find the right bearing material for your application.We’re here to support you. Start a conversation with our team today. |

Simplify Your Workflow with MCAM Connect

Easily manage orders, access critical data, and get tailored support — all from one powerful platform.