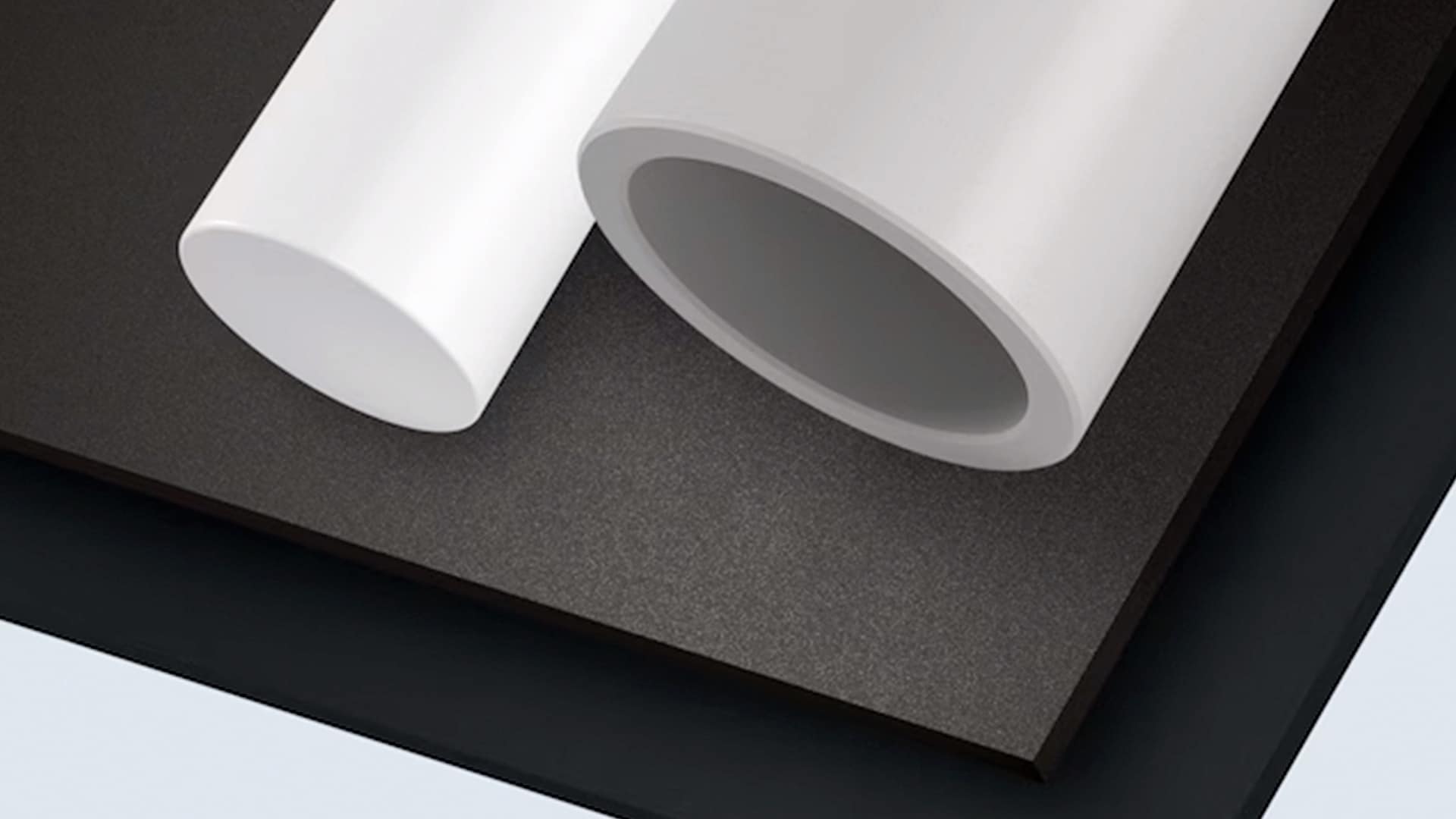

Some jobs push standard polytetrafluoroethylene (PTFE) beyond its limits. That’s why Mitsubishi Chemical Group (MCG) developed the Fluorosint™ family of enhanced PTFE materials over 50 years ago. Back then, it was created to bring greater reliability and strength to applications where ordinary PTFE materials fell short. Today, Fluorosint™ is a trusted choice for designers and engineers who need more from their materials.

Why Fluorosint™?

Fluorosint™ isn’t merely filled or reinforced PTFE. Think of it as “PTFE Plus.”

MCG technology involves a unique process that chemically links virgin PTFE to synthetic mica produced in-house. This results in a bond that enhances the overall performance of PTFE to provide:

Better load strength. |

Excellent dimensional stability across wide temperature swings. |

Low wear and low friction. |

Chemical and electrical properties similar to unfilled PTFE. |

In other words, Fluorosint™ retains the chemical resistance, low friction, and heat tolerance of PTFE—then takes them further. This makes Fluorosint™ a stronger choice in applications where standard PTFE can struggle to meet performance targets over time.

Meet the Three Core Grades

Each Fluorosint™ material is made for high stress, abrasive environments where bearings, bushings, and seals need to work hard and hold up for the long haul. These trusted options excel wherever you need to resist chemicals, reduce friction, and handle heat beyond the basic performance of regular PTFE.

Grade |

Key Properties |

Ideal Applications |

| Fluorosint™ 500 |

|

|

| Fluorosint™ 207 |

|

|

| Fluorosint™ HPV |

|

|

Where Performance Meets Partnership.PTFE isn’t one-size-fits-all. When the spec gets tricky, we’re here to help. Reach out to your MCG team today. |

Simplify Your Workflow with MCAM Connect

Easily manage orders, access critical data, and get tailored support — all from one powerful platform.