Finding the Right TIVAR® Solution

Mitsubishi Chemical Group (MCG) designed TIVAR® ultra-high molecular weight (UHMW) polyethylene to provide the perfect balance of performance and machinability for your finished parts.

Mitsubishi Chemical Group (MCG) designed TIVAR® ultra-high molecular weight (UHMW) polyethylene to provide the perfect balance of performance and machinability for your finished parts.

Engineers prioritize performance to ensure parts last longer and systems run more efficiently. With over 20 enhanced grades, MCG offers the right TIVAR® solution for your application.

Grade |

Unique Characteristics |

Common Applications |

| TIVAR® ESD | Eliminates static charge build up | Conveyor guides |

| TIVAR® DrySlide | Self-lubricating and antistatic | Package handling chutes/slides and wear pads |

| TIVAR® UV | UV protection in direct sunlight | Outdoor service, e.g., dock fenders |

| TIVAR® Oil Filled | Self-lubricating due to an oil additive | Seals and conveyor guides |

| TIVAR® CeramP | Higher surface hardness and stability | Wear pads, valve seats/seals, and parts requiring more wear resistance |

| TIVAR® 88 and 88-2 | Higher surface hardness and stability with additives for enhanced release properties | Bulk material handling system liners for hoppers, chutes, and storage bins |

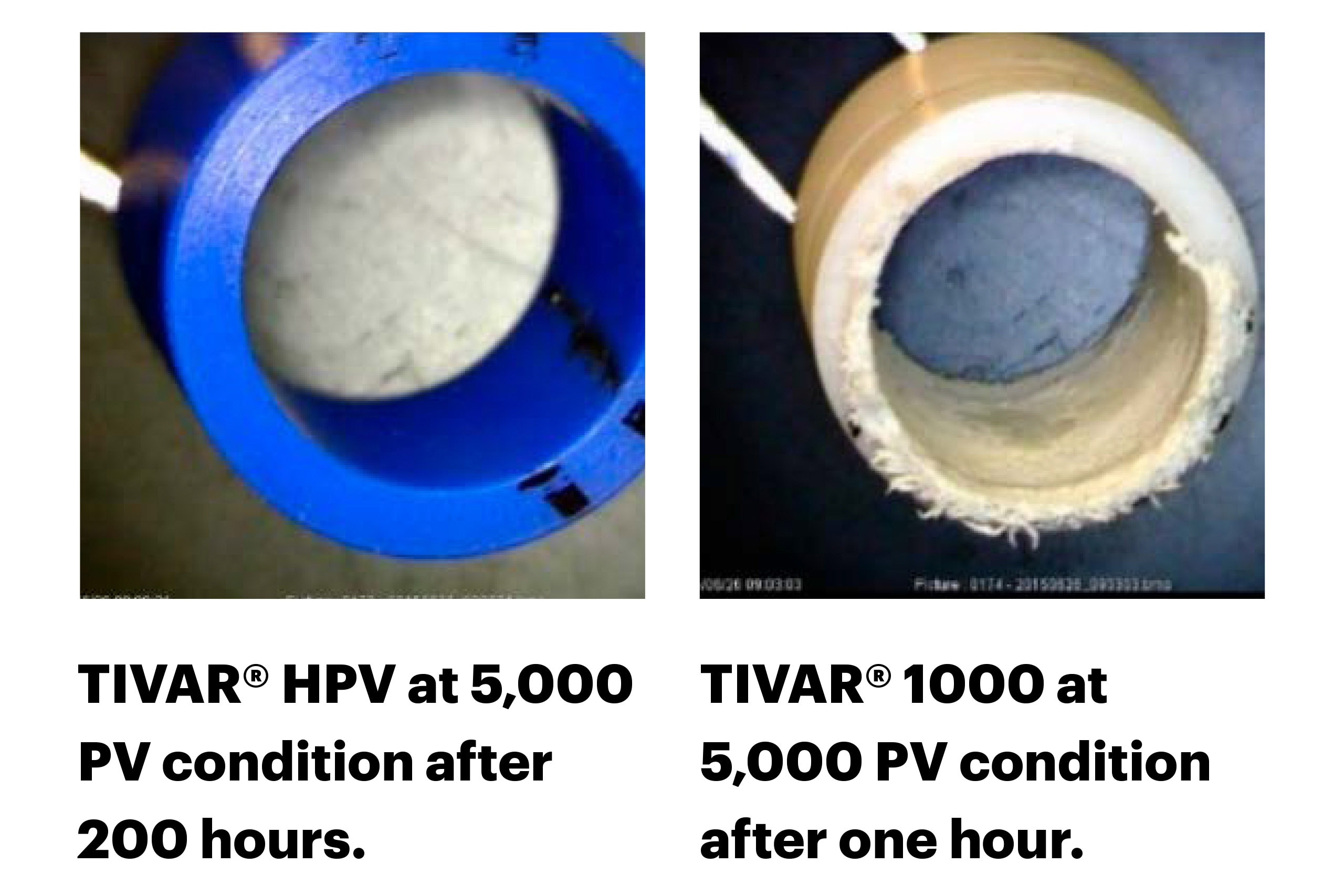

| TIVAR® HPV | Self-lubricating and lowest wear rate/highest limiting PV among UHMW grades | Conveyor curves and guides where line speeds are too great for other UHMW grades |

| TIVAR® VMX | Blue color that provides visual, metal, and X-ray detection | Food industry components that must be detectable should debris enter the process stream |

| CleanStat | Eliminates static charge and is FDA compliant | Food industry components, especially those near electronics like metal detection systems |

| TIVAR® HOT | Thermally stabilized to extend the continuous operating temperature to 250° F | Conveyor guides and bearings operating within or near a heat source (oven) |

TIVAR® HPV is engineered to keep systems running faster and eliminate the need for grease. It’s ideal for situations where:

TIVAR® HPV is designed to handle this by:

Bearings, bushings, and conveyor guides benefit from TIVAR® HPV in key ways:

TIVAR® HPV is available in plates, rods, tubes, and custom profiles.

We know machinists value:

That’s why we deliver the most options for TIVAR® plate so you can deliver what your customers want.

Process |

Advantages |

Disadvantages |

| Lorien thicknesses (¼" to 2") |

|

|

| Pressed thicknesses (3/8" and greater) |

|

|

| Skived thicknesses (less than ¼") |

|

|

| Planed thicknesses (¼" and greater) |

|

|

Need more information?Our MCG team is ready to help. Contact us today to find the right TIVAR® solution for your needs. |

Simplify Your Workflow with MCAM Connect

Easily manage orders, access critical data, and get tailored support—all from one powerful platform.